Mixing container

Classification:

- Description

-

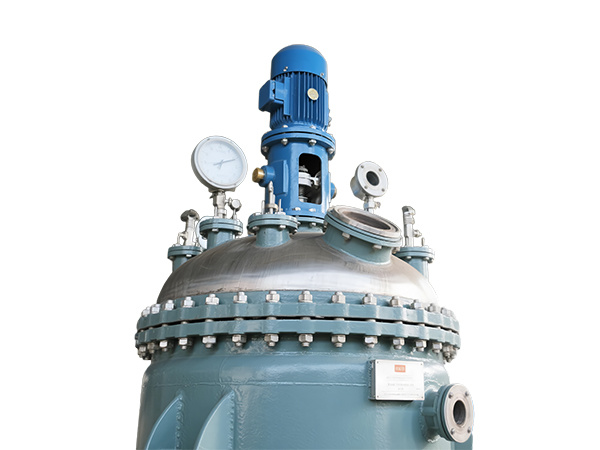

Mixing vessels are often called mixing tanks (or mixing vats). When mixing equipment is used as a reactor, it is also called a stirred tank reactor, sometimes abbreviated as a reactor.

Structural Form

1. Dimensions and Specifications of the Cylinder

The structure of the tank is usually a vertical cylindrical shape. The height-to-diameter ratio mainly depends on the operating liquid height-to-diameter ratio and the loading factor. The liquid height-to-diameter ratio of the container varies depending on the properties of the materials in the container, the mixing characteristics, and the number of agitator layers. Generally, it is 1~1.3, and the maximum can reach 6. The bottom of the tank can be flat, elliptical, conical, etc., and sometimes a square tank can also be used. At the same time, according to the heat transfer requirements of the process, a jacket can be added to the outside of the tank, and heat transfer media such as steam and cooling water can be passed through; when the heat transfer area is insufficient, coils can also be installed inside the tank.

2. Material of the Cylinder

The material of the mixing vessel must meet the requirements of the production process, such as pressure resistance, temperature resistance, resistance to medium corrosion, and ensuring product cleanliness. Due to the different materials, the manufacturing process and structure of the mixing vessel are also different, so they can be divided into steel mixing equipment, glass-lined mixing equipment, and lined mixing equipment. The purpose of lining is to resist corrosion or protect the cleanliness of the product. There are many types of linings, mainly including stainless steel, aluminum, titanium, lead, nickel, zirconium, acid-resistant ceramic tiles, greenstone plates, and rubber.

3. Installation Method of the Impeller

The impeller is usually inserted vertically into the tank from the center of the top of the mixing tank. Sometimes, side insertion, bottom insertion, or side insertion methods are also used.

4. Internal Components of the Cylinder

Internal components include baffles, coils, guide tubes, gas distributors, etc.

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.