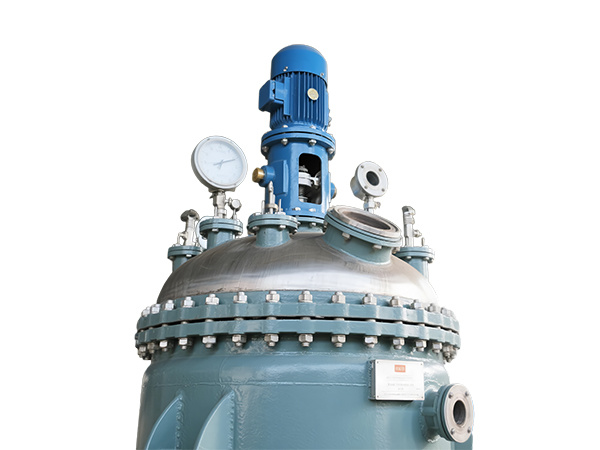

Reactor

Classification:

- Description

-

The reactor is a comprehensive reaction vessel. The design of the reactor's structure, function, and configured attachments based on reaction conditions allows for the completion of pre-set reaction steps from initial feed, reaction, and discharge with a high degree of automation. It strictly controls key parameters during the reaction process, including temperature, pressure, mechanical control (stirring, aeration), and reactant/product concentration.

Reactors are widely used in petroleum, chemical, rubber, pesticide, dye, pharmaceutical, and food production industries, as well as various scientific research and experimental projects. They are used as vessels to complete processes such as hydrolysis, neutralization, crystallization, distillation, evaporation, storage, hydrogenation, hydrocarbonization, polymerization, condensation, heating and mixing, and isothermal reactions.

Structural Form

The reactor consists of a vessel body, vessel cover, jacket, stirrer, transmission device, shaft seal device, and support. Stirring methods generally include anchor type, paddle type, turbine type, propeller type, or frame type, etc. For reactors with greater height, multiple layers of stirring blades can be used. Options can also be customized according to user requirements. A jacket is installed on the outside of the vessel wall, or a heat exchange surface is installed inside the vessel. Heat exchange can also be achieved through external circulation.

Heating methods include electric heating, hot water heating, heat transfer oil circulation heating, far-infrared heating, and external (internal) coil heating, etc. Cooling methods include jacket cooling and internal coil cooling. The form of the stirring blades, etc., can be customized. Support bases include support type or lug type. For speeds exceeding 160 rpm, a gear reducer should be used. The number and specifications of openings can be designed and manufactured according to user requirements.

Nominal Capacity

(L)Design Pressure

(MPa)Design Temperature

(℃)Inner Pot Dimensions

(mm)Jacket Dimensions

(mm)Gearbox Model Motor Power

(kw)Electric Heating Power

(kw)50 0.1-10.0 150-350 400 500×600 BLY type 0.6-1.1 3×2 100 0.1-10.0 150-350 500 600×700 BLY type 0.6-2.2 6×2 200 0.1-10.0 150-350 600 700×800 BLY type 1.5-2.2 300 0.1-10.0 150-350 700 800×900 BLY type 1.5-2.2 6×3 500 0.1-10.0 150-350 900 1000×1100 BLY type 2.2-4.0 9×4 1000 0.1-10.0 150-350 1200 1300×1400 BLY type 4.0-0.55 12×4 1500 0.1-10.0 150-350 1300 1400×1500 BLY type 4.0-1.5 2000 0.1-10.0 150-350 1400 1500×1600 BLY type 4.0-7.5 15×4 2500 0.1-10.0 150-350 1500 1600×1700 BLY type 4.0-7.5 3000 0.1-10.0 150-350 1600 1700×1800 BLY type 7.5-11 15×4 4000 0.1-10.0 150-350 1600 1800×1900 BLY type 7.5-11 15×3 5000 0.1-10.0 150-350 1800 1900×2000 BLY type 7.5-11 18×5 Steam Heated Stainless Steel Reactor 6000 0.1-10.0 150-350 2000 2000×2100 BLY type 11-15 18×5

Specifications

(L)Electric Heating Power

(kw)Inner Pot Dimensions

(mm)Jacket Dimensions

(mm)Oil Jacket Capacity

(L)Outer Diameter Dimensions

(mm)Gearbox Model Motor Power

(kw)Stirring Speed

(r.p.m)Weight

(kg)30 3×2 Φ350 Φ550 50 Φ718×1900 BLB type 0.55 85 250 50 3×2 Φ400 Φ600 75 Φ824×2015 BLB type 0.75 85 270 100 6×2 Φ500 Φ700 130 Φ1004×2120 BLB type 1.1 85 340 200 6×2 Φ600 Φ800 150 Φ1104×2300 BLB type 1.5 85 700 300 6×3 Φ700 Φ900 180 Φ1208×2495 BLB type 2.2 85 700 500 9×4 Φ900 Φ1100 280 Φ1468×2695 BLB type 22 85 930 1000 12×4 Φ1200 Φ1400 420 Φ1896×3110 BLB type 4.0 85 1610 2000 15×4 Φ1400 Φ1500 740 Φ2005×3500 BLB type 5.5 85 2010 3000 15×4 Φ1600 Φ1800 1300 Φ2165×3600 BLB type 7.5 85 2590 4000 12×4 Φ1700 Φ1900 1500 Φ2265×3800 BLB type 11 85 3160 5000 18×5 Φ1800 Φ2000 1800 Φ2370×4000 BLB type 15 85 4100 6000 Φ2000 Φ2200 1900 Φ2570×4700 BLB type 15 85 4500 8000 Φ2200 Φ2400 2100 Φ2900×4700 BLB type 18.5 85 6170 Electrically heated stainless steel reaction kettle 10000 Φ2400 Φ2600 2400 Φ3150×4900 BLB type 22.5 85 7050

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.