Organic heat transfer fluid heater

Classification:

- Description

-

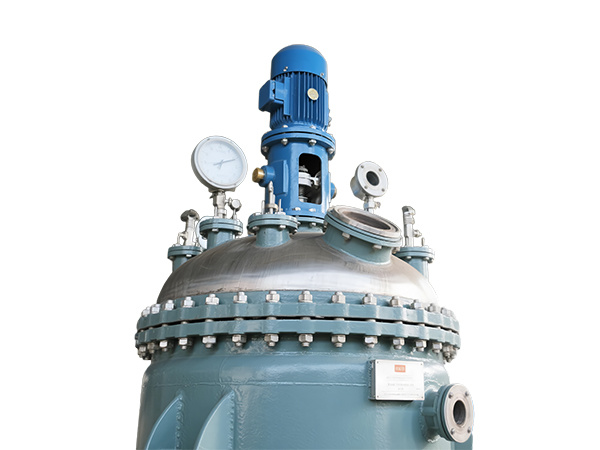

The oil (gas) vertical (horizontal) series organic heat carrier furnace is a quick-assembly forced circulation oil (gas) boiler. This series of boilers has a compact heating surface structure, and the heating surface is composed of densely arranged circular tubes inside, middle, and outside (or inside and outside). The inner circular tubes are the radiation heating surface, and the middle and outer circular tubes and the outer surface of the inner circular tubes constitute the convection heating surface. The fuel burns and releases heat in the combustion chamber formed by the inner circular tubes. After absorbing most of the heat through the radiation heating surface, the high-temperature flue gas enters the convection heating surface for heat exchange. Finally, the low-temperature flue gas is directly discharged from the boiler flue gas outlet to the chimney and discharged into the atmosphere. The installation is extremely convenient and flexible; just place the boiler on its foundation.

The heating surface adopts densely arranged circular tubes, with sufficient heating surface arrangement, reducing the heat load on the surface of the tubes, making the use of heat transfer oil safer. The furnace size matches the combustion flame, and positive pressure combustion is adopted, with high radiation heat exchange efficiency. The boiler structure is compact, greatly saving the floor space of the boiler room. Large boilers have air preheaters installed at the rear to improve boiler efficiency.

Rated thermal power: 350~3500KW Working pressure: 0.8MPa

Boiler Model YY(Q)L(W)-

350Y(Q)YY(Q)L(W)-

600Y(Q)YY(Q)L(W)-

900Y(Q)YY(Q)L(W)-

1200Y(Q)YY(Q)L(W)-

1500Y(Q)YY(Q)L(W)-

1800Y(Q)YY(Q)L(W)-

2300Y(Q)YY(Q)L(W)-

2900Y(Q)YY(Q)L(W)-

3500Y(Q)Heating capacity ×104kcal/h 30 50 75 100 130 150 200 250 300 Design efficiency % ≥90 ≥90 ≥90 ≥91 ≥91 ≥91 ≥91 ≥91 ≥91 Working pressure Mpa 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 Maximum operating temperature ℃ 320 320 320 320 320 320 320 320 320 Medium circulation m³/h 40 58 100 100 100 160 160 200 240 Main pipe diameter DN 100 100 125 125 125 150 150 200 200 Installed capacity kw 10 15 28 36 44 54 50 60 60 Applicable fuel Oil, gas In-furnace medium capacity m³ 0.2 0.42 0.7 0.8 1.1 1.2 2.0 2.6 3.0 Fuel coal consumption kg/h 36/45 64/75 89/108 125.6/153.4 155/188 164/173 245.2/302.8 293/345 357/433 Maximum transport size m 1.6×1.4×1.85 2.0×1.7×2.65 3.4×1.9×2.0 3.5×2.2×2.1 4.6×2.3×2.2 4.7×2.5×2.3 5.2×2.8×2.65 5.3×2.8×2.75 6.2×2.8×2.8 Maximum transport weight t 1.2 3.9 5.2 5.5 7.3 8.6 13.6 15 20 Note: Our company's products are constantly being improved and perfected; the parameters listed in the table are for reference only.

Rated thermal power: 4700~14000KW Working pressure: 0.8MPa

Boiler Model YY(Q)L(W)-

4700Y(Q)YY(Q)L(W)-

5900Y(Q)YY(Q)L(W)-

7000Y(Q)YY(Q)L(W)-

8200Y(Q)YY(Q)L(W)-

9400Y(Q)YY(Q)L(W)-

10500Y(Q)YY(Q)L(W)-

12000Y(Q)YY(Q)L(W)-

14000Y(Q)Heating capacity ×104kcal/h 400 500 600 700 800 900 1000 1200 Design efficiency % ≥91 ≥91 ≥91 ≥91 ≥91 ≥91 ≥91 ≥91 Working pressure Mpa 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 Maximum operating temperature ℃ 320 320 320 320 320 320 320 320 Medium circulation m³/h 260 300 240 400 520 520 600 680 Main pipe diameter DN 200 250 250 250 300 300 300 350 Installed capacity kw 85 100 120 140 170 195 200 250 Applicable fuel Oil, gas In-furnace medium capacity m³ 3.7 4.5 7 8.2 9.5 12 13 14 Fuel coal consumption kg/h 459/557 573/696/ 688/835 803/975 918/1115 1087/1314 1147/1393 1377/1671 Maximum transport size m 6.8×3.2×3.3 7.4×3.3×3.4 7.8×3.35×3.5 8×3.5×3.6 8.4×3.6×3.65 8.8×3.7×3.8 9.7×3.7×3.8 11.2×3.7×3.8 Maximum transport weight t 29 37 47 53 58 65 80 108 Note: Our company's products are constantly being improved and perfected; the parameters listed in the table are for reference only.

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.